Custom Design & Fabrication

Custom Design & Fabrication

The biggest problem we face when trying to solve a troublesome issue is where to start. Let’s face it, textiles, F.O.D. covers, shipping covers, long term storage covers probably do not fall in your wheelhouse. Fortunately, they land right in ours. We pride ourselves on working with our customers to solve any problems they have and maybe even some they didn’t know they have.

Working Together

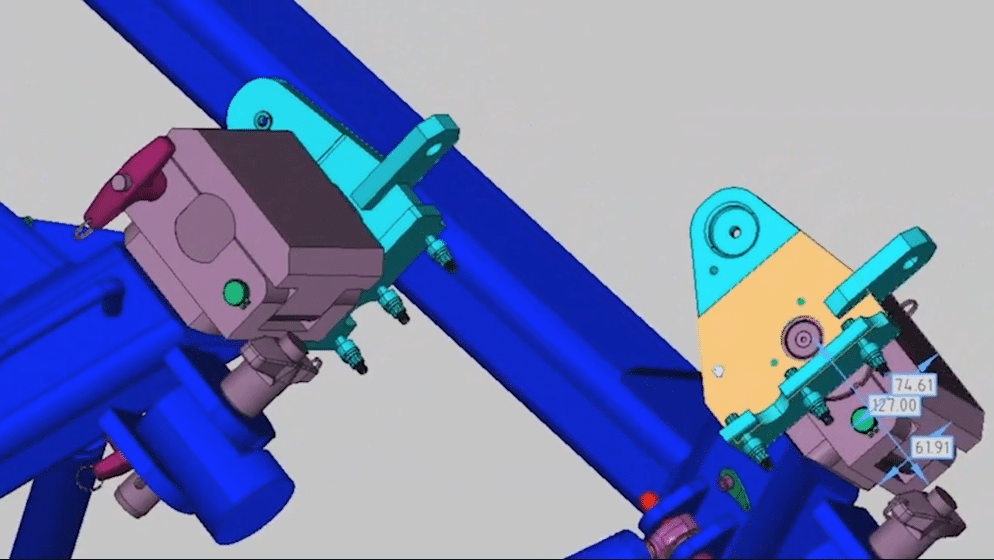

UITP’s Master fabricators have years of experience both in designing covers from scratch and working off of our customers’ existing blueprints. We apply our expertise to making your vision a reality. Read more about our commitment to quality, here.

On-Site

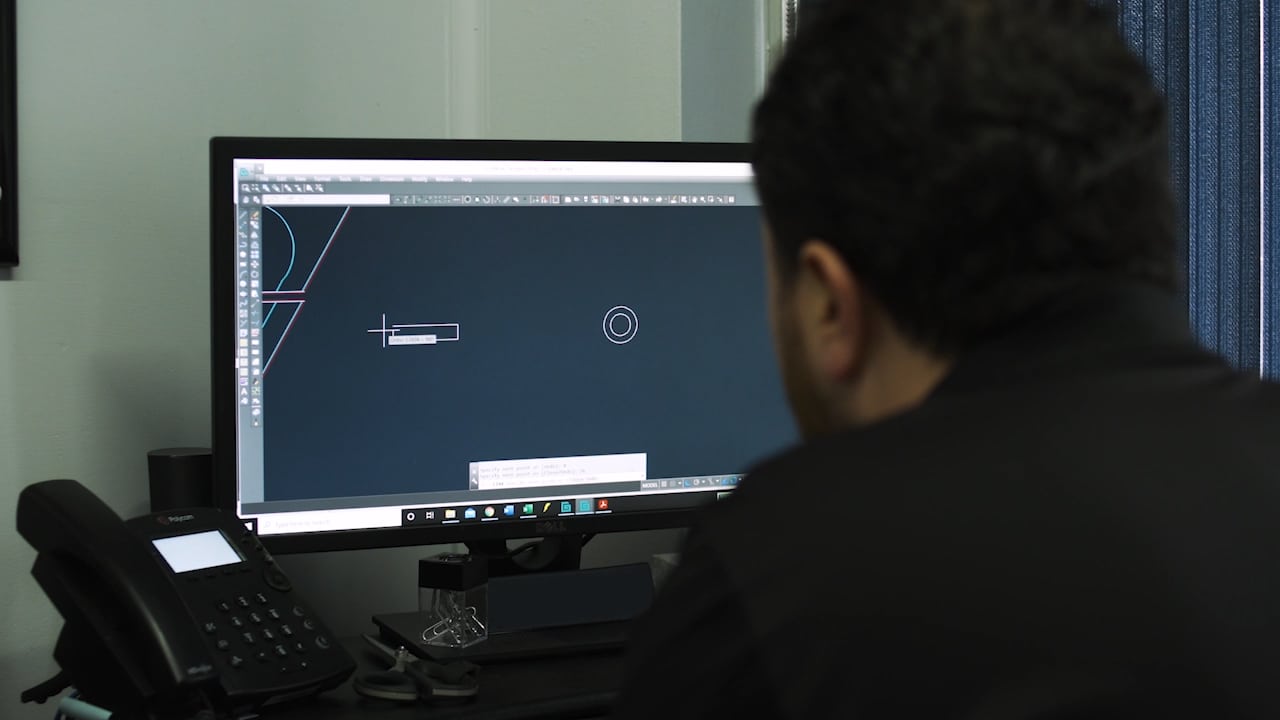

In the event that you do not have a design already in mind or blueprinted, we offer on-site consultations. We will gather the dimensions and point out any potential problem areas. Our fabricators will then work with you to come up with a design that will meet all of your requirements.

Technology

We utilize some of the most advanced textile equipment during the design phase. We design all our covers through CAD software and run them through our high speed automated cutting machines. Forced heat, wedge and RF sealing machines, as well traditional sewing methods are all available. This equipment allows us to produce a wide range of products specifically targeted to serve your individual needs.

Custom Printing

You spend a lot of time designing and building the products that you deliver to your customers. Your company name should be proudly displayed the day that it is delivered to them. Our print department has the ability to create custom screens of your logo, and any required warnings or labeling. We can print your artwork onto your cover, displaying it front and center – letting your customers know that you built it and you stand by it.